How drones and AI are revolutionising the inspection of wind turbines

Wind turbines must be regularly inspected as an important requirement for maintaining insurance cover. Sending out teams of inspectors in climbing gear, however, is not just time-intensive and costly, it is also dangerous. In collaboration with a technology partner, Funk is offering its clients an innovative and much more efficient solution: Funk SmartInspect WEA.

Challenge: meeting complex insurance requirements

For operators of wind turbines, carrying out inspections and maintenance is standard practice for ensuring the safety and reliability of the wind turbines. In the process, reports are generated with standardised criteria for meeting obligations and therefore maintaining insurance cover. In order to perform one of these regular inspections, the wind turbine is stopped and a team of inspectors is sent up in climbing gear to the nacelle from which they access the rotor blades. The rotor blades are each brought to the 6 o’clock position one after the other and prepared for the inspectors to climb onto them. The blades are then manually inspected and any irregularities are logged and photographed. The entire process usually takes several hours, during which the turbine is not working and therefore not generating any yield for the operator. The related documentation process is also manual, without identifying the exact location of the irregularities; notes on this must be added after the fact. As a result, it is currently difficult to compare the reports and the associated data.

This procedure is not just time-intensive and costly, but also very often inefficient. This is because any damage identified during inspections can often only be repaired later during a separate visit to the turbine. As turbines get bigger and bigger and increase in number, the risks to the inspection team and the scope of the manual job continue to grow. Last but not least, these inspections depend heavily on weather conditions and can only be performed by skilled and qualified personnel.

Drone/UAV

A UAV (unmanned aerial vehicle) is an aircraft without a human pilot on board, steered via remote control or software application by a pilot. In general speech, the term ‘drone’ has become common parlance. Depending on the application, drones are equipped with cameras, special sensors or small loads for transport.

Solution: inspecting turbines with drones and artificial intelligence

In collaboration with its Beyond Insurance partner FairFleet and selected clients from the wind power sector, Funk has developed an innovative process based on drones and artificial intelligence (AI) to specifically meet these challenges. Funk SmartInspect WEA is a turnkey Beyond Insurance solution that offers clients technology, intelligent analysis and recommendations all in the same package. It offers operators a faster and more efficient way to standardise wind turbine inspections and continue to ensure that insurance requirements are met. The client does not have to invest in hardware or software or provide a trained drone pilot – all of this is included in the scope of service.

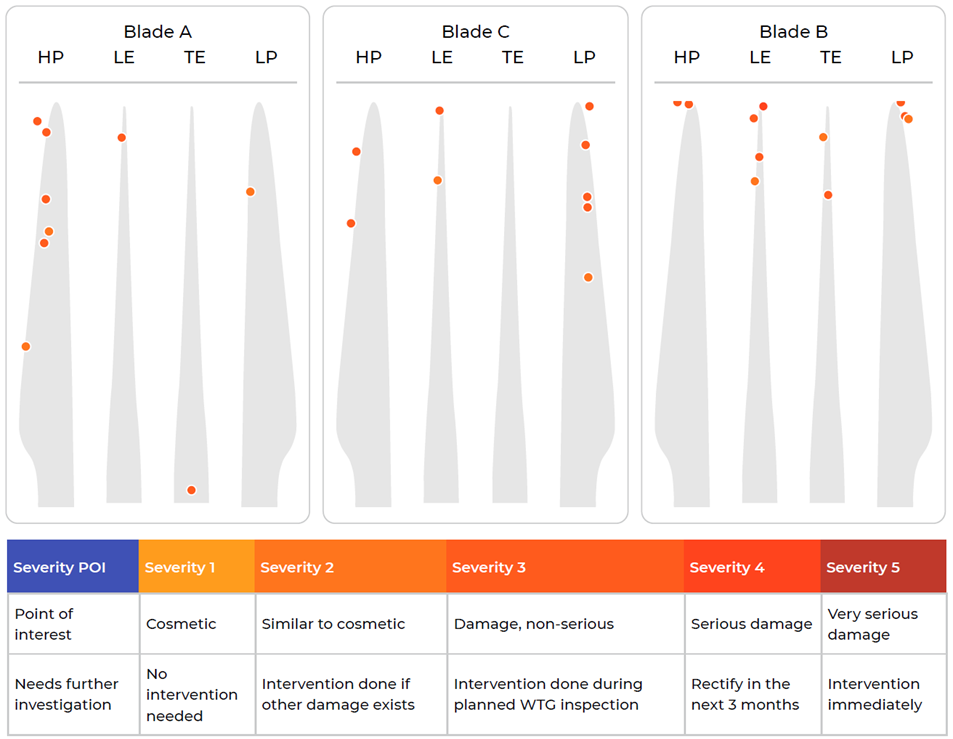

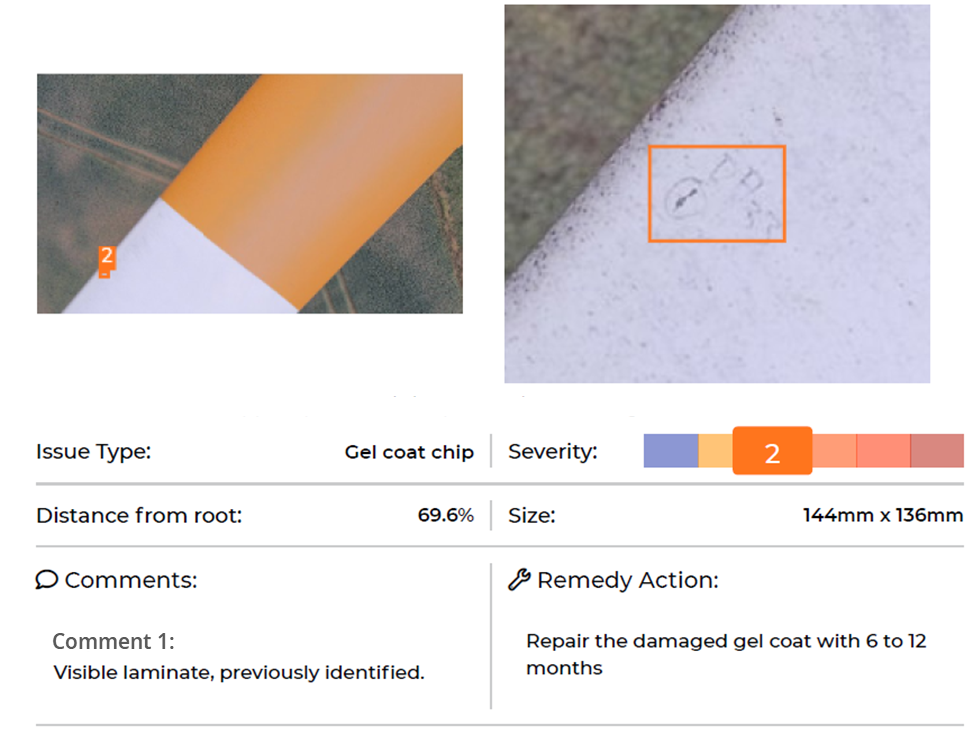

The client sees at a glance where damage is and how severe it is. © FairFleet

FairFleet has developed a standardised flight protocol specifically for use with wind turbines, whereby an automated image log is created after the turbine is measured. For this purpose, the turbine is stopped at a prescribed position, and then fixed points are recorded by the drone and the flight protocol is started. The drone then automatically follows the prescribed flight pattern and photographs the turbine from multiple angles. The photos are later analysed with intelligent algorithms and compiled in an automatically generated report. Irregularities are identified using the photos and recommendations are made. Based on previous measurements of the turbine, the location of any deviations can be identified and therefore easier be found during subsequent maintenance and repair tasks.

Initial Funk clients are permitted to conduct the inspections using this method under protection of their insurance cover. The solution is not connected to an individual insurer, but rather implemented by Funk for interested clients across the breadth of the market, in consultation with the desired insurer.

Artificial intelligence (AI)

AI is an umbrella term for software-based applications that replicate the intelligent performance of the human brain – learning, making judgement calls and solving problems. It is essentially based on algorithms for calculating probabilities and detecting patterns in extensive datasets. The most important feature of AI methods is the ability to learn, whereby the application not only makes decisions based on prescribed, memorised examples it has been fed, but is also able to generalise knowledge gained and apply it correctly in practice. Thanks to these methods, AI applications are constantly improving over time and performing the tasks they have been assigned better and better.

The high-resolution cameras on the drones find even the smallest defects, unlike the human eye. © FairFleet

Benefit: increased efficiency through innovative methods

Companies should not use modern technology just for the sake of it, but rather to solve real problems and create measurable advantages. Using drones can make wind turbine inspections even more efficient and, above all, more standardised. The reports generated based on this technology contain standardised criteria and always include the same benchmarks. The resulting homogeneous data is optimised for analysis and can be easily compared, so that correlations can be identified more easily. The detailed reporting with image logs also ensures greater traceability of irregularities and targeted improvements. And there’s another benefit: gone are the days of sending inspection teams on dangerous climbs up the turbine, a risky mission especially when weather conditions are poor. Now the teams only have to go up if there is a genuine need to do so. Last but not least, operators can increase the efficiency of their turbines because downtime is reduced and the improved quality of the analysis means that faults due to wear and tear or overlooked damage are more unlikely.

With Funk’s support, all of the commercial benefits of this innovative and efficient method of inspection can be realised directly and used to meet insurance requirements. Use Funk SmartInspect WEA to bring the inspection of your wind turbines to the next level!

Want to inspect other targets – such as photovoltaic systems – more intelligently and efficiently? More information on the general use of drones and AI, an example of how a project might progress and the transferability of this technology to other problems can be found in the Beyond Insurance case study ‘How drones detect damage to photovoltaic systems’.

Your point of contact

Technical aspects

Wind turbines

Drones

Artificial intelligence

Benefits/objectives

Risk assessment and

documentation

Time and cost savings